A small practical scale test was carried out in 2009 using the new SAMCO cultivation machine. It started off with a coincidental encounter between Hein-Willem Leeraar & partners and a number of Irish farmers. This specific cultivation technique was observed during a study in 2008. Hein-Willem Leeraar & partners set the wheels in motion and was responsible for arranging the delivery of the machine in the spring of 2009 following additional fact-finding missions in 2008 and January 2009, which involved meetings with the system manufacturer, end users and dealers. Heeringa Cultuurtechniek BV persuaded farmers to provide a number of plots, a total of 25 hectares which could be used at that time for pilot studies. The Heeringa technical staff also had to learn how to use the machine. The Irish manufacturer organised a dedicated 10-day course, which was given by lecturer and designer Robert Shine. Rutger Agricola and Willem Johannes Heeringa participated in the course and rounded it off successfully.

Heeringa employees operate the SAMCO cultivation machine and supervise the professional process of covering the maize.

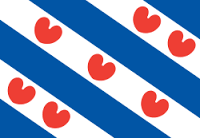

It quickly became evident that all previous knowledge had to be thrown overboard. There was good reason to promote the system under the name of Samco System, with the emphasis on ‘system’. Different methods were needed for soil preparation, the same applied to sowing technique and variety selection, and changes were also needed in respect of crop protection and fertilising. If a film– which is fully biodegradable – is tensioned above the soil, then the soil is warmed up at a rapid enough rate to initiate changes to the conventional way a number of processes function when it comes to growing maize. In turn, the Irish had no experience whatsoever with the Northern soil types, which are encountered on a regular basis in the three northern provinces of the Netherlands (Friesland, Groningen, Noord Holland). The diversity of these soil types across minimal distances was a particularly surprising element. In concrete terms, the stumbling blocks were the organic matter content and the “knip clay” complex; this concerned seedbed preparation, but also the way the machine operates. The machine was modified in the autumn of 2009 to suit the Dutch circumstances.

The aim for the first year was clear: to harvest a qualitative and quantitative crop much earlier than usual, so that Heeringa Cultuurtechniek BV could promote the system and the additional costs were set-off for the end users.

The 2009 results were quantitatively below the mark, but they were exceptionally good in qualitative terms, however, ultimately this was merely a one-year trial and the outcome did not form a strong enough basis to sway the balance, given the additional costs, required investments etc.

Furthermore, keeping a –scientifically substantiated – record of the environmental effects is a must: reducing N use and activating soil life by avoiding compaction caused by alternative processing times. The latter is not only beneficial in terms of improving the soil structure; it also contributes to the agro-biodiversity, which includes fungi, bacterium and soil life. Less compaction means less damage to the soil life.

The search for more suitable (forage) maize varieties for this system is a long-term process. Fertilising and crop protection must be location specific.

The biodegradability of the type of film used on lighter soils was also too lengthy, which meant that other types had to be used for research purposes.

The research results must ultimately form an economic basis for the decisions to invest by all parties involved.

User & society a joint interest

The objectives:

-

Optimising maize cultivation by improving the profitability (= no structure damage, higher yield, improved contents of macro and micro elements, use of the land throughout the entire year), resulting in economic durability and improved animal health;

-

Reducing nutrient use through location specific application and consequently reducing nutrient leaching;

-

Increasing biodiversity of the soil life by preventing compaction

-

Increasing the yield within the (forage) maize cultivation sector (greater choice in variety selection); by using varieties from groups that are normally not used in North-Netherlands: (forage) maize varieties from the middle maturing or late maturing group. These varieties require more growing days than the traditional ‘early’ varieties. More growing days are available due to the earlier sowing and the accelerated germination process.

-

Facilitating and promoting post crop cultivation i.e. sowing a green manure crop.

The Nutrient Management Institute (NMI) also plays an important role in the project as a contract research partner.

In relation to objective 1: during harvesting, 1 full trailer per plot is weighed at the weighbridge (empty weight already noted), surface measured that relates to the full trailer, convert into hectare yield in kg product, take sample and send to Agrarisch Laboratorium Noord-Nederland in Ferwert = quality analysis. The analysis results are then interpreted and translated into ‘farmer’s language’ by experts ir. G. Schaaf and ing. J.Kuipers MAB. Individual feedback to participants and group presentation in December.

In relation to objective 2: two routes are monitored here; in the first instance the 16 participating farmers agreed to observe ‘tailor-made fertiliser advice’, soil samples are taken from all plots at arable land level (20-25 cm depth); all participating farmers take part in manure analysis. This is used as a basis for fertilising recommendations which are then issued under the supervision of ir.G. Schaaf and these are subsequently observed. Secondly, research is carried out by the NMI in order to determine whether or not the film concerns a more rapid mineralisation of N (as a result of the soil warming up due to the film applied). The mineralisation is measured on three plots; each plot is divided into sections with film and sections without film. The measurements also take place at three different times. The nylon bags incubation technique is used. Temperature sensors are installed. Hypothesis I 2010: as a consequence of the soil warming up more rapidly and earlier, the N present becomes available for the plant at an earlier stage and this is why a lower fertiliser N-addition is adequate.

In relation to objective 3: the NMI also performs the research here in conjunction with Hein-Willem Leeraar. A visual inspection is held at approximately 10 locations at the end of 2010. 5 of these locations were (forage) maize under film 5 were not. Soil testing will take place in the spring of 2010, whereby soil characteristics will be established. Number and type diversity of saprophagous eelworms will be determined, as well as the total counts for fungi and bacterium, using BFI (a type of soil life index). Penetrometer tests will also be performed. Bulk density, pore volumes and pH characteristics will be determined.

Hypothesis II 2011: structure damage / compaction will be avoided as a result of the new cultivation system and this contributes to an improved (beta) biodiversity i.e. improved soil life (subsequently beneficial to (forage) maize plant and farmer)

In relation to objective 4: other varieties are used than were used in 2009; later varieties in particular and a pilot field will be created where 10 different varieties will be sown for comparative purposes at Elsloo. Students monitor growth on pilot plots. Reporting in tables and graphs for presentation at group presentation.

In relation to objective 5: a number of participants will be asked to sow a green manure crop, which guarantees the absorption of nutrients in the autumn. This also causes an improvement in the structure of the soil during the subsequent spring.

We refer to the Economy appendix in the report in relation to the economic viability of the crop.